The history of metal garden furniture is a tricky one. It is very much linked to the history of garden design and the history of metal furniture in general. The three are intrinsically linked.

It makes this a complicated article to write. There's very little in the way of source materials. And what does exist is a little contradictory or a little on the dull side.

However, as we found with our popular origins of Lazy Susan post whereby we dove into the history of the revolving serving tray from which we derive our name, it is often a fascinating journey to try and map out, make sense of and make it an interesting read.

Of course, the temptation here is to drift off on a myriad of tangents. For example, the sections we drafted on the history of metal lawn chairs, deckchairs and sun loungers have been popped into the article “ideas” folder and will probably get their own post in the future.

All that said, the Lazy Susan team are up for the challenge here and, by understanding the back story, hopefully, we can illustrate how and why metal garden furniture has become one of, if not the dominant material on our patios.

What is metal garden furniture?

The most succinct definition of “metal garden furniture” we could think of is any form of furniture item that is designed for outdoor use (i.e. weather resistant) and constructed from primarily metal parts such as aluminium, iron or steel.

Of course, these are materials that are also utilised extensively in many other furniture applications, ranging from office chairs and cabinets to kitchen tables and bed frames, however, durability and versatility are what have made metal perfectly suited for outdoor use.

But just like there are advantages and disadvantages to the different types of popular outdoor furniture materials, be it wood, resin or metal, for example, so too there are (albeit often more subtle) differences between the different types of metal garden furniture.

The “big 3” metals in the UK garden furniture industry are cast aluminium, stainless steel and cast or wrought iron.

When we talk about “cast” metal it is the process of pouring the molten metal into a sand-cast mould to form the parts needed, whilst wrought is where the alloy (most commonly iron) is heated and worked into shape with tools.

As we state on our how it’s made page:

“Sand casting is an ancient moulding method that can be traced all the way back to 4000 BC.”

In their History of Metal Casting article, the Warner Brothers Foundry say that:

“The earliest metal castings were made with gold and copper — because these metals were extremely malleable, they were easy to melt and cast. Bronze soon replaced them, however, due to its rigidity and strength. The earliest bronze castings were made using open stone moulds.”

MetalTek traces the origin of casting back to Around 1300 BC and the Shang Dynasty:

“China were the first to utilise sand casting when melting metals. Then around 500 BC, the Zhou Dynasty invented cast iron, but it was used mostly for farmers. Cast iron did not become a military tool or decoration until the Qin Dynasty almost 300 years later.”

Wrought metals too can also be traced back just as far, with many historians establishing that it began to take the place of cast bronze in Asia Minor around the 2nd millennium BC, and by the 3rd century BC it was the primary material for the production of tools and weapons across the globe.

The Reliance Foundry in their article looking at the difference between cast and wrought iron state that:

“Wrought iron was used as early as 2000 BC in the Anatolian peninsula (now Turkey), and it was widely used in construction throughout the 19th century. Advancements in metallurgy in the 20th century, however, have made it easier and less expensive to machine-form and weld metal parts.”

All of this, of course, makes establishing a true history of metal garden furniture extremely difficult.

Much of it is lost to the sands of time. What we do know is that while the process of metal casting is an ancient one, the use of aluminium is a much more recent discovery.

It was first discovered by Sir Humphrey Davy in 1807, and he called this magical new material “alumina”. In their history of cast aluminium article, Premier Tables say:

“The first discovery of aluminium took place in 1807 in England. Sir Humphrey Davy called the new metal “alumina.” However, the process he used to create the metal, which consisted primarily of pouring acid onto clay, left a product that he was unable to extract from the bonded oxygen particles. Nearly 15 years later, in 1821, a Frenchman named Berthier discovered Bauxite ore in Les Bauxs, France. This discovery was instrumental in the eventual mass production of aluminium, as Bauxite ore is the raw material used in current aluminium production. A few years after the discovery of Bauxite, which contains roughly 50% alumina, a Danish scientist known as H.C. Oerstedt produced the first batch of what we now call aluminium. However, it wasn’t until the end of the 19th century that a process for mass production was perfected.”

Here at Lazy Susan, our collection is constructed from a high-grade sand cast aluminium with a strong focus on classical styling and patio dining, so you can see why we have a keen interest in unravelling the history of metal garden furniture.

But for us, the decision to focus on this material, was a logical choice as we found it best suited to the UK climate:

- It will not rust like steel and iron

- It is durable and can be further enhanced with painted finishes

- It is just as sturdy as steel and iron.

- It is fully weatherproof,

- It is the lowest conductor of heat

- It is more affordable than steel and iron

- It is significantly lighter than other metals so it can be moved around the garden and stored if need be.

Of course, cast iron is still a popular choice for outdoor furniture too but it requires significantly more maintenance than cast aluminium as it is highly susceptible to rust.

Stainless steel on the other hand is used extensively for more modern pieces as it has a high tensile strength but whilst the hollow tubes reduce weight they also limit you in terms of design and the shapes that can be formed.

Wrought iron garden furniture, whilst expensive and labour-intensive to create, can still be found in our industry. However, they are often antique pieces that have been restored or new pieces produced by an artisan craft company or traditional blacksmith.

The origins of metal garden furniture

While many think of metal garden furniture as a “modern” material, much like the production technique, the origins go back much further.

Far from being a new thing, it has been around for many many centuries, and in his book Bent Wood and Metal Furniture (1850-1946), Derek E. Ostergard suggests that references to chairs made from iron date back as early as ancient Rome.

In Western Europe during the Middle Ages, wrought iron was a popular choice for furniture frames on chests and beds for those who could afford it as it was better suited to the damp and was more resistant to bugs and rot than the more common timber frames.

However, more often than not furniture was constructed from hardwoods such as oak, ash, elm, and beech and iron was used for fixings at this time.

In fact, the first known item of metal furniture to go on general sale was much later, although who got there the first is up for much debate.

One checkpoint in the timeline that many agree on is the critical role played by Prussian architect and highly respected designer, Karl Friedrich Schinkel.

In our opinion, it is he who is the true grandfather of metal garden furniture in particular.

His first piece was a simple round three-legged cast iron table that he introduced in 1820, but in about 1825 he started producing his first cast-iron garden furniture designs for the gardens of the Prussian royal palaces.

On display at the V&A museum in South Kensington, London you will find a garden armchair based on his design and manufactured circa 1835 to 1865 (pictured above).

The museum describes it in its literature as follows:

“This chair is based on a design of about 1835 for the Römischen Bäder (a garden pavilion known as the Roman Baths) in the gardens at Potsdam. The design was produced for about thirty years by foundries all over Europe, with slight variations in the detail of the back, arms and feet. Without archival evidence, it is very difficult to date such chairs precisely.”

Around 1840 in America, Janes, Beebe & Company produced one of the earliest mass-produced cast-iron garden benches, and you can find a marked example in the Smithsonian Institute (pictured above). Commonly referred to as the “twig bench”, they describe it as follows:

“This bench imitates the wooden furniture found in nineteenth-century naturalistic gardens. Cast iron eliminated the need to search for the necessary tree branches to complete the design and offered more structural integrity. The design consists of dried oak branches with a few remaining leaves that have been laid asymmetrically and bound together with cords to form the back, seat, and arms. On the stretcher between the front and back legs are a pair of intertwined serpents coiled around the legs nibbling at oak leaves below the seat. This design disregarded comfort in favor of achieving the Rustic aesthetic.”

Steel indoor and outdoor furniture pretty much came along at the same time and it grew in popularity during the Bauhaus movement of the 1920s.

According to Wikipedia:

“Around 1925, Marcel Breuer, the Bauhaus furniture designer and architect, began working with tubular steel, having been impressed with the light weight and strength of the handlebars of a bicycle. The resulting furniture designs by Breuer and others using this material are some of the most important of the period. In the United States during the 1930s, designers such as Gilbert Rohde and Wolfgang Hoffman specialised in indoor tubular chrome plated furniture, while Warren McArthur was the preeminent maker of high-end aluminium tubular furniture.”

The article goes on to say how production was halted during World War II as factories supported the war effort but when it ended many, such as Arvin Industries, switched to the production of metal lawn furniture and dinette sets during the 40s.

The Wikipedia entry goes on to say that:

“When the war ended, a new consumer society developed, and Arvin began producing products for the home such as electric irons and ironing boards, waffle makers, radios and, by 1949, its first television set. It also began once again to manufacture outdoor steel furniture. By the 1950s, in addition to tubular steel, furniture was produced using aluminium, wire mesh and legs made of thin steel rods that give mid-century furniture its distinctive splayed leg, light-on-its-feet look.”

The history of metal furniture in the UK

Here in the UK during the 1830s, towards the tail end of the Industrial Revolution, we saw a dramatic increase in the use of iron across our construction industry, particularly in our rapidly expanding rail network.

At this time, the country also saw the material make its way into our homes as furniture, and in particular outdoor metal furniture. At the forefront of this boom was the Birmingham-based Coalbrookedale Company which rose to prominence during the 1840s.

The organic lines of the Coalbrookdale foundries garden benches, tables and chairs became synonymous with Victorian garden design and even Queen Victoria herself was known to have several pieces.

Much of the styling from their collection can still be found in our own range of metal garden furniture, and our London Rose Bistro Set (pictured above) is inspired by their cast iron garden chairs.

If you don’t mind the cost and ongoing maintenance, you can still pick up vintage Coalbrookdale garden furniture from antique dealers and furniture restoration companies too.

The popularity of metal furniture did hit a notable decline during the Art Nouveau period (from the 1880s until the First World War), as people shunned mass factory production for arts and crafts.

However, in the 1920s and 30s metal started to make a comeback thanks to influential furniture designers such as Stam, Van der Rohe, Salterini, Leinfelder, Woodward and Breuer.

However, it wasn’t until the 1950s that metal really came back with a bang, thanks primarily to the design innovation of US-based Charles Eames and Harry Bertoia. They in particular took metal furniture (tubular steel primarily) mainstream and made it more desirable to the masses, where it has remained popular ever since.

A brief history of garden furniture

In terms of garden furniture, it has a history as old as gardens themselves, they go hand in hand. For as long as we have enjoyed our outdoor spaces, we have needed a place to sit.

This is probably an article all of its own (and one we may again revisit) but we wanted to take a look at the history of garden furniture in general to see how it all fits together and when metal came into play.

As far back as ancient Egypt there is archaeological evidence of rattan-style furniture made from woven reeds and grasses.

In ancient Rome, digs at sites such as Pompeii have uncovered villas with outdoor seating dating back as early as 43 AD and ornate garden benches were an integral part of Roman garden design.

In medieval times the garden became more of a space for growing food, and whilst there was significantly less emphasis on leisure, there is still evidence of places to sit and enjoy the fruits of your labour.

One of the popular styles was a turf bench, whereby a stone, timber or wattle and daub framework is backfilled with stones and earth and planted with grass for sitting on.

During the Renaissance period was when we the people truly fell in love with the concept of the garden as a space of beauty, relaxation and enjoyment again.

The French led the way and their immaculate symmetrical designs creating the demand for outdoor seating that was just as romantic and sophisticated.

Although common practice at the time for many of the well-to-do was to literally bring the “indoors outdoors”. Dining tables and chairs were carried outside, set up and dressed up with fine china on manicured lawns or gravel patios when they wanted to entertain guests.

One of the most enduring trends in our industry, and a style that is still incredibly popular to this day, is the bistro table.

Appearing in Parisienne cafes as early as the 1600s, these intimate dining tables were all over the city of light by the 1800s and arguably introduced the masses to the concept of outdoor dining.

The bistro-style garden chair, from which so much of our collection and many others still take inspiration, is generally credited to German-Austrian cabinet maker, Michael Thonet.

Best known for working with bentwood (made by wetting wood, bending it and letting it harden into curved shapes), his No. 14 cafe or bistro-style chair (pictured above) is a design that has been much imitated.

As metalworking techniques and materials improved over the 19th century decorative ironwork bistro sets started to appear as a more durable alternative.

Thonet’s chair was also arguably one of the first pieces of furniture designed to be shipped in parts to save space during transportation (something we also still do to this day).

As we mentioned earlier, in this country it was certainly the Victorians who made metal garden furniture de rigueur.

Their love of parks as spaces to meet and relax and frequent trips to the seaside for a bit of tiddly-on-pom-pom created a boom in demand for outdoor furniture that could stand up to the not-so-great British weather.

Cast iron was the logical choice (being more durable than wood) and their sophisticated Rococo-influenced designs started making the jump from public spaces to their own back gardens.

Following the Second World War, large-scale aluminium production was on the rise and families were embracing home and garden design in even great numbers.

Cast aluminium allowed for greater flexibility in terms of design and significantly lower production costs, so the finished product looked like ironwork but was more affordable, durable and required significantly less maintenance than its metal counterpart.

Today, outdoor furniture is big business, we value our outdoor living spaces, and the garden is up at the top on most people’s home improvement to-do lists.

In the UK in 2022, the average household spent around £700 upgrading their outdoor space, and according to Google, searches for garden and patio furniture have increased by over 125% in the last two years.

The global garden furniture market was valued at around 40 billion pounds last year and that is projected to grow to 45 billion this year and (at current growth rates) could reach as high as 60 billion pounds by 2030.

Metal garden furniture continues to be the most popular and logical choice of material in the UK due to its durability, weather resistance, low maintenance, and as we’ve hopefully shown in this article, it has a very interesting, if foggy, history too!

Looking for new metal garden furniture?

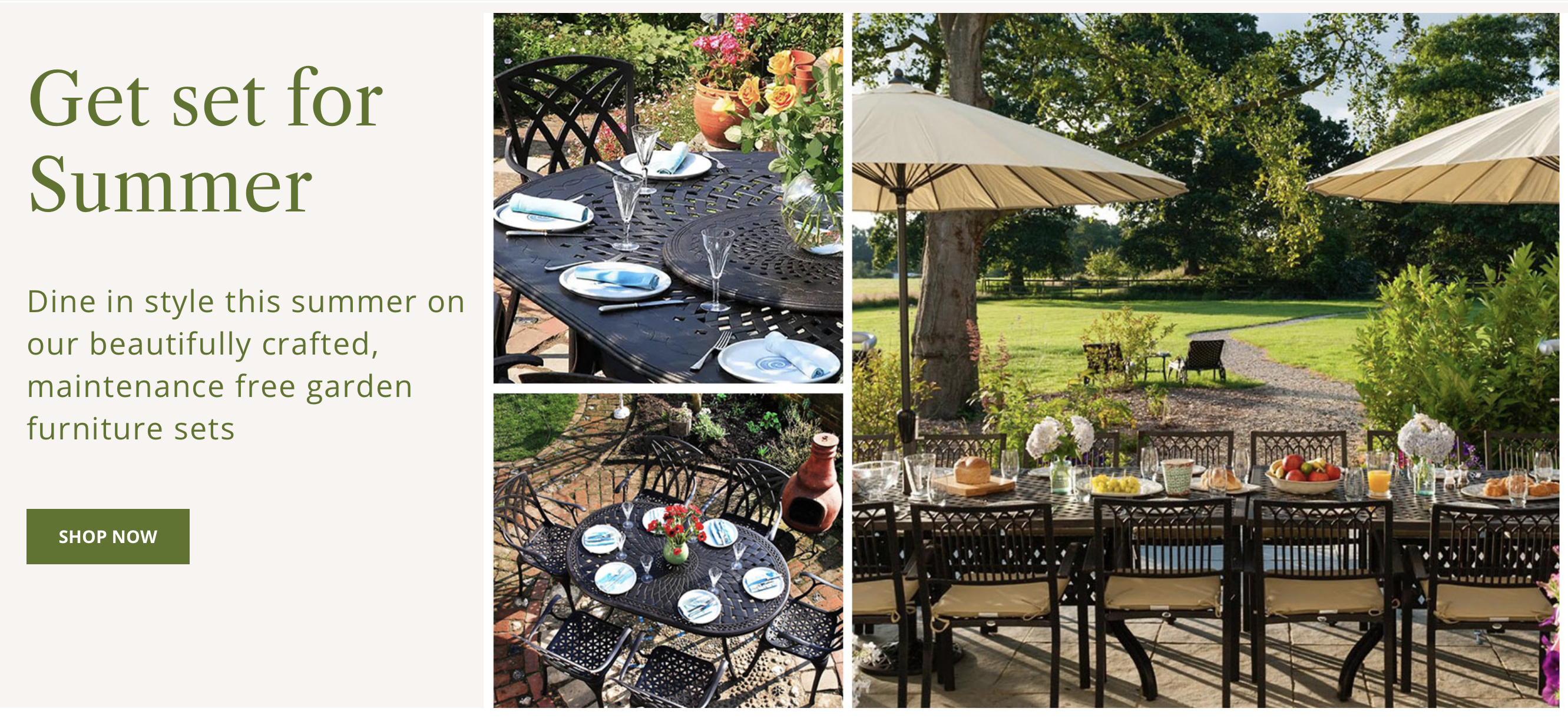

Get set for Summer with Lazy Susan.

Dine in style this summer on our beautifully crafted, maintenance-free garden furniture sets

Shop Now

If you’re still doing your research, then please sign up for our newsletter to hear about any future news, competitions, promos, sales and discounts.

You can sign up below in the orange box below!

If you have any photographs of our Metal Garden Furniture on your patio, then we’d love to see a few for our Do Some Good charity campaign.

You can tag us @LazySusanFurniture on Instagram or Facebook or email them to us direct at [email protected].