We like our history articles here at Lazy Susan. Not many others in the garden furniture industry seem to do them but we think it's fascinating to learn the origins and etymology of the various pieces we sell.

The downside is that there’s not a lot of info out there so these posts can take a bit of researching. Putting them into some sort of logical order is no easy task too as there's so much conjecture and supposition that the sorting of fact from fiction can be impossible.

That said, our history of Lazy Susans and Bistro Sets have both proven to be very popular articles, so we thought we’d tackle the garden bench.

We gave a brief overview of the history of garden benches in our Complete Guide, so we want to do it a little differently this time and focus specifically on cast iron benches.

For us, the garden bench is the quintessential piece of outdoor furniture, and they have become synonymous with cast iron.

You find them both in our private and public outdoor spaces (where they are often an iron frame with timber slats) and, whilst they’re available (both now and historically) in a host of other materials, cast iron is the one from which many (us included) still draw inspiration.

Of course, we predominantly use cast aluminium for our outdoor furniture range, but we will explain the reasons why, and why much of our industry has also shifted over from iron to aluminium later in the article.

What is cast iron?

Cast iron is a class of iron-carbon alloys with a carbon content greater than 2%, and it has a relatively low melting temperature, so it is a great choice for moulding into the pieces needed for outdoor furniture.

It is made by melting iron ore in a blast furnace, and much like we still do with our aluminium, the molten metal is then poured into moulds or casts, where it cools and solidifies.

Cast iron can be cast into a variety of shapes and sizes, and it’s still used in a wide range of applications such as engine blocks, flywheels, brake discs, cookware, pipes, valves, machine tools, and of course, outdoor furniture.

It is a strong and durable material, and it is also easier and cheaper to make than its artisanal wrought counterpart, making it a popular choice for a wide variety of furniture applications.

What are the advantages and disadvantages of cast iron?

Like all materials in our industry, there are advantages and disadvantages with cast iron. No material is perfect for outdoor use, and what some see as a negative, such as say weight, others will see as a positive, and vice versa.

What we would determine as the main advantages of furniture made from cast iron are that it is strong, durable, relatively inexpensive to produce, it can be cast into a variety of shapes and sizes, and it is easy to clean.

On the downside, it is a high conductor of heat, it can be brittle, incredibly heavy, and is highly susceptible to rust and corrosion, so requires regular maintenance to keep it weather-resistant.

Who invented cast iron?

The invention of cast iron is credited to the ancient Chinese, who developed the process in the 5th century BC or possibly earlier.

According to Han Rubin and Chen Jianli in their publication Casting Iron in Ancient China:

“The casting of iron in ancient China was a significant invention that occurred during the 5th century BC or earlier (Han 2000). Due to the absence of historical records regarding iron technology in this early period, scholarship concerning early iron production must rely on the archaeological record. Iron artefacts have been metallographically studied, and the earliest worked iron was meteoric iron, which was made into blades during the middle of the Shang Dynasty period”

One thing is sure, the Chinese use of cast iron predates the earliest European evidence of cast iron production by a few millennia.

We also know that the basic method of production has not changed, and the Chinese would melt the iron ore in a furnace and then pour the molten iron into moulds to make a variety of products, such as agricultural tools, weapons, and cookware.

Cast iron production was not introduced to Europe until the Middle Ages, but it quickly became a popular widespread production technique.

It was used to make a variety of products from cannons to bridges and buildings, and was a key component in the industrial revolution.

In the late 18th century, during the Industrial Revolution, the invention of the steam engine enabled the blasting of air into the furnace by machine, which subsequently made the mass production of iron possible.

What is the difference between cast iron and wrought iron?

We touched on this in above but we just wanted to clarify that whilst both are iron alloys, they have different properties, a different production process, and they are used for different purposes:

1. Cast Iron:

Cast iron is made by melting iron ore in a blast furnace and then pouring the molten iron into moulds. It has a high carbon content (more than 2%), which makes it strong and durable. However, it is also brittle, meaning that it can break easily if dropped or hit hard. Cast iron is also susceptible to rust and corrosion.

2. Wrought Iron:

Wrought iron is made by heating iron ore and then hammering it into shape. It has a lower carbon content (less than 0.08%) than cast iron, which makes it less strong and durable but also less brittle and more malleable. Wrought iron is also more resistant to rust and corrosion than cast iron.

What is the history of the cast iron garden benches?

Historians have traced the origins of the cast iron garden bench back to the 18th century.

The first were made in England, and they quickly became popular throughout Europe and the United States, due to their durability, weather resistance and the fact they were cheaper to mass produce than wrought iron and timber benches.

Originally designed and sold for use in public parks and gardens, they soon became a popular addition in private gardens too.

They were often decorated with elaborate designs in an attempt to recreate the ornate wrought metalwork of a blacksmith at a fraction of the cost (and in greater numbers for mass consumption).

By the late 19th and early 20th centuries, the cast iron bench was experiencing a boom in this UK, partly due to the rise of the emerging middle class.

With more disposable income than previous generations, they were eager to invest in their homes and gardens, and the garden bench was seen as a symbol of status and prosperity.

One of the leading purveyors of English outdoor furniture at this time was Coalbrookdale, a family-owned company based in Shropshire and founded in 1709.

Famed for their cast iron, they started out sand-casting cookware and parts for steam engines, but by the mid-1800s the company were developing lines of highly decorative garden furniture.

According to the British and Irish Furniture Makers Online (BIFMO):

“Founded in 1709 by Abraham Darby (1678-1717), the company originally made iron parts for engineering and building industries, with its technique of coke smelting a key innovation of the early Industrial Revolution. The manufacture of decorative castings, such as railings and park gates, began in the early 19th century under Francis Darby and rapidly expanded in the 1830s. A decade later the company was making domestic metal furniture.”

Today, the cast iron bench is still a popular choice in our public spaces. They’re a classic and timeless piece of furniture, and whilst other better-suited materials have become more popular in our own gardens, you can still purchase them.

Some of the more well-known cast iron benches found around the world include:

The Central Park Benches, New York City

The Memorial Benches in Hyde Park, London

The Trevi Fountain Benches in Rome, Italy

The Jardin du Luxembourg Benches in Paris, France

Why are most modern metal benches now made from cast aluminium?

As we mentioned above, whilst cast iron is still a popular material in public spaces, in our own gardens we have seen a big shift to other metals such as cast aluminium and stainless steel.

Here at Lazy Susan, we love the timeless styling of cast iron but when we created our collection cast aluminium proved to be a more logical choice.

It is much better suited to the UK climate and, as the production technique is much the same, we can create the same beautifully ornate metalwork in that timeless style.

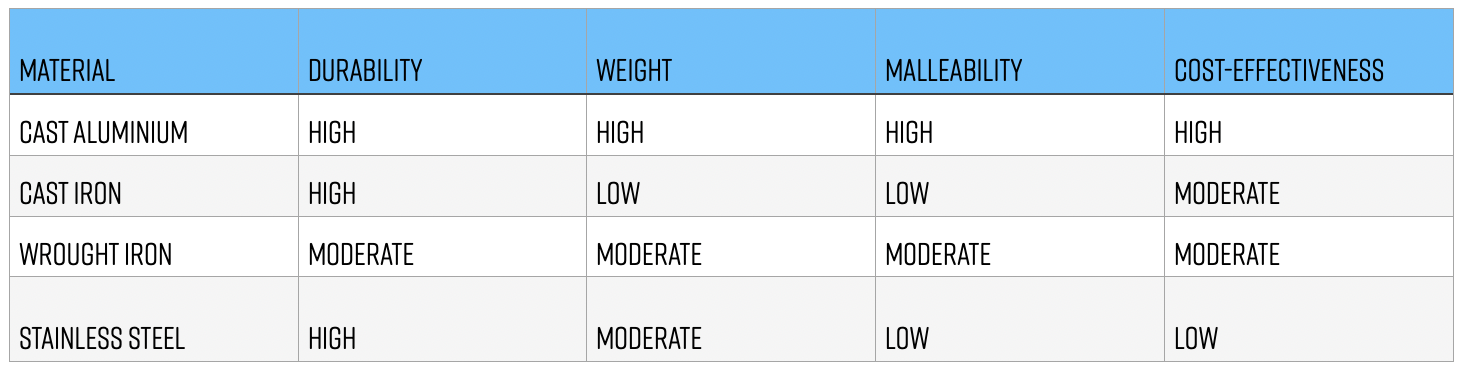

The table below compares cast aluminium to other popular materials used for metal benches:

We found when testing that aluminium has a number of distinct advantages over iron, and this is why it is used to make most modern metal benches for the garden:

-

Durability

The big advantage that cast aluminium has over cast iron is that it is a stronger and more durable material that’s resistant to corrosion and rust. Instead, if you expose raw aluminium to the elements it will oxidise, whereby a powdery white coating will form. This oxidation will harden and create a protective layer and prevent it from corroding. We actually further protect the metal by applying a tough powder-coat-like finish so it can withstand the elements without deteriorating over time. It can withstand harsh weather conditions, and you can leave it out in rain, snow, and sun, so it is perfect for garden benches. -

Weight

Weight is another critical factor, and with cast aluminium bench being a much lighter-weight material, it is easier to move and transport. The heaviness of iron is a logical choice for our public benches, but in the home, the ability to move it around the garden for practical reasons or storage is a big plus point. However, despite that lightness, it still retains the same, if not greater, strength and stability of iron. -

Malleability

It is also a much more malleable material, which basically means that we can cast it into a wider variety of shapes and sizes, with a significantly lower chance of cracking. This allows us to create benches with unique and eye-catching designs, and we can do this without having to heat the alloy to a lower temperature than you would need with iron. -

Cost

Cast aluminium is cheaper to produce than iron, making it a cost-effective metal. And, whilst it is generally more expensive than other popular materials such as wood or plastic, the initial higher price will deliver better value for money in the long run as it will not require the same level of maintenance and is more weather-resistant. It is resistant to rust, corrosion, and the elements, so it can withstand years of outdoor use without requiring much time and money spent to keep it looking like new. -

Maintenance

As we’ve just mentioned cast aluminium requires little to no maintenance. Unlike iron, it does not need to be repainted regularly with a specialist paint to prevent rust. It can simply be cleaned with soap and water when necessary. We would also advise you to apply a light coat of car wax or sealant every few months or so to help protect it from the elements and give it a nice sheen. This low-maintenance aspect is particularly advantageous in our gardens where we want our furniture in the garden, ready to use when the sun shines, without the need to spend precious time and money keeping it looking good. -

Environment

Cast aluminium is also easier to recycle than iron, which aligns with our increasing focus on sustainability and reducing environmental impact. It is one of the most recyclable materials in the world, with a recycling rate of over 70%. This means that a large proportion of cast aluminium products can be recycled and reused, which reduces the need to extract and process new raw materials. However, it is important to be aware of the environmental impacts associated with products we buy and repair, up-cycle or recycle our old furniture when it is showing its age.

These factors have seen much of our industry switch to cast aluminium over iron for our gardens and even many of our public spaces.

As you can see, cast aluminium offers a number of advantages over other materials used for metal benches. This is why it is the most popular material for modern metal benches.

Of course, there are plenty of benches made from other materials, such as wood, resin, steel, cast and wrought iron. If you’re unsure which one is best for your outdoor space, then before you click buy our Complete Guide to Garden Benches looks at the pros and cons in detail and has a host of information on how to pick the right size, style, price, etc.

However, in our opinion, cast aluminium is the preferred material for most modern benches due to its classic styling, durability, lightweight design, low maintenance, production malleability, and cost-effectiveness.

If you have any photos of your Lazy Susan Garden Bench, we’d love to see a few for our Do Some Good charity campaign. You can tag us @LazySusanFurniture on Instagram or Facebook or Upload Here.